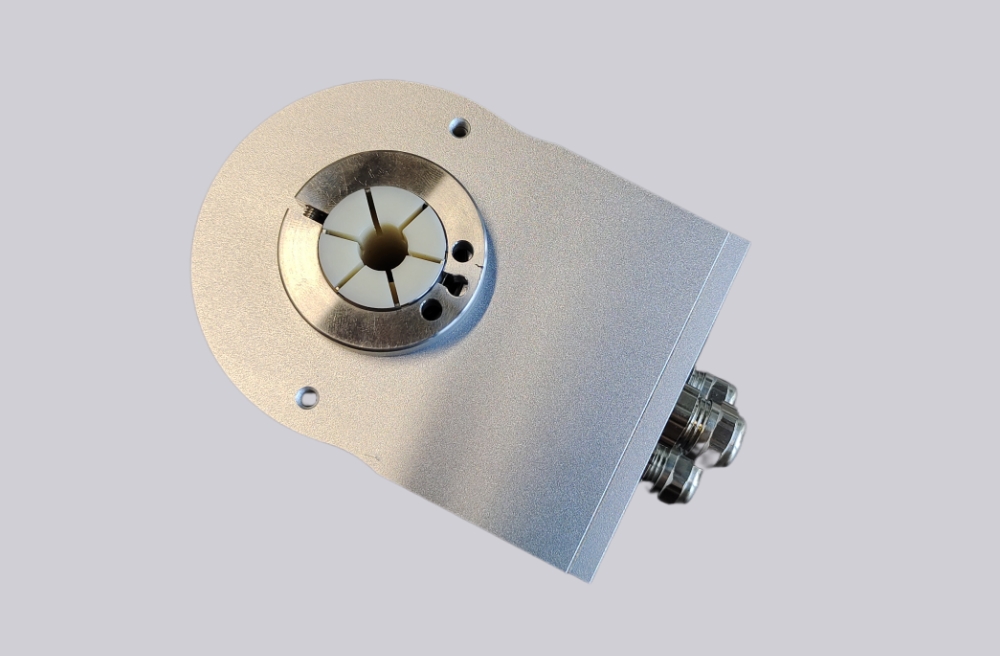

A rotary encoder is an industrial sensor used to measure rotational position, angle, or speed. It is widely applied in industrial automation, machinery, energy systems, and motion control equipment. By converting mechanical rotation into electrical signals, rotary encoders provide accurate and stable feedback to control systems and play a critical role in modern industrial applications.

Basic Working Principle of Rotary Encoders

A rotary encoder typically consists of a rotating shaft, a sensing element, and signal processing electronics. As the shaft rotates, the internal sensing structure generates electrical signals corresponding to the angular position or movement. These signals are then interpreted by the control system to determine position, direction, or rotational speed.

Depending on the sensing technology, rotary encoders may use optical, magnetic, or other non-contact detection methods. Optical encoders are known for high resolution and precision, while magnetic encoders offer better resistance to vibration, dust, and harsh environmental conditions.

Incremental and Absolute Rotary Encoders

Based on output signal characteristics, rotary encoders are generally classified into incremental encoders and absolute encoders.

Incremental encoders generate pulse signals to indicate relative movement. They are commonly used for speed monitoring and position control applications. While incremental encoders provide fast response and simple structure, they cannot retain position information after power loss and require a reference reset upon restart.

Absolute encoders output a unique position value at any time, allowing the system to determine the exact shaft position even after power is restored. Absolute encoders are available in single-turn and multi-turn versions and are widely used in applications requiring high positioning accuracy and system reliability.

Communication Interfaces and System Integration

With the advancement of industrial control systems, rotary encoders must support reliable communication in addition to accurate measurement. Common communication interfaces include RS232, RS485, SSI, CANopen, PROFIBUS, Profinet, and analog output signals. Each interface offers different advantages in terms of real-time performance, noise immunity, and system architecture, and should be selected based on specific application requirements.

Environmental Considerations in Encoder Selection

Industrial operating environments significantly influence encoder selection. In industries such as oil, metallurgy, and chemical processing, equipment often operates under high temperature, heavy vibration, or dusty conditions, requiring encoders with robust housings and high protection ratings. In hazardous areas, explosion-proof rotary encoders must be used to ensure safe and reliable operation.

Conclusion

Rotary encoders are essential components in industrial control systems. A clear understanding of their working principles, classifications, and communication options enables engineers to select suitable encoders for specific applications, improving system stability, accuracy, and long-term performance.

SIVIDI

请到「后台-用户-个人资料」中填写个人说明。

Latest Articles

Copyright © 2025 SIVIDI Inc. All Rights Reserved. Sitemap