In the technical specifications of rotary encoders, resolution and accuracy are two of the most frequently referenced parameters by engineers, yet they are also among the most commonly misunderstood. In many industrial projects, excessive emphasis is placed on high resolution while the overall system accuracy is overlooked, often resulting in increased cost without a corresponding improvement in performance. From an engineering perspective, a correct understanding of the relationship between resolution and accuracy is essential for proper encoder selection.

1. Definition of Resolution and Its Engineering Implications

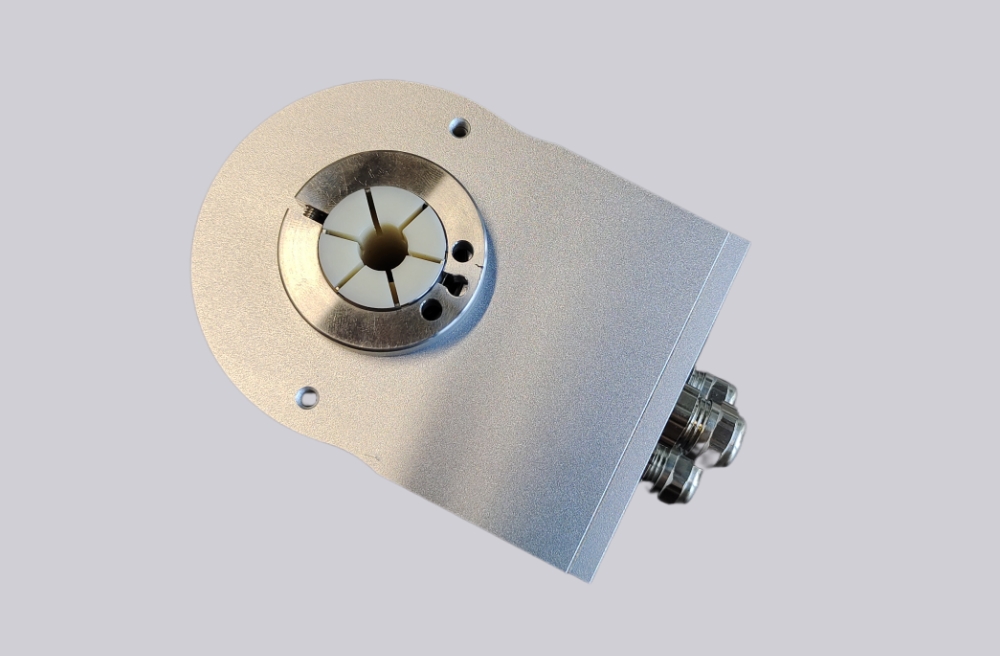

The resolution of a rotary encoder describes the smallest detectable angular increment within one mechanical revolution. For incremental encoders, resolution is typically expressed as pulses per revolution (PPR), while for absolute encoders it is usually specified in bits, such as 12-bit, 16-bit, or higher.

A higher resolution allows finer angular subdivision and, in theory, provides more detailed position feedback for motion control systems. This can be beneficial in applications requiring precise positioning, smooth speed regulation, or complex motion profiles. However, in practical engineering applications, resolution alone does not determine the achievable control precision of the system.

The effective resolution is also limited by the controller’s sampling rate, signal processing capability, and the bandwidth of the communication interface. If the control system cannot fully utilize the encoder output data, an excessively high resolution may offer little practical benefit.

2. Practical Meaning of Accuracy and Repeatability

Accuracy refers to the deviation between the encoder’s measured value and the true mechanical position. Unlike resolution, which defines the level of detail, accuracy reflects how closely the measured position corresponds to the actual position.

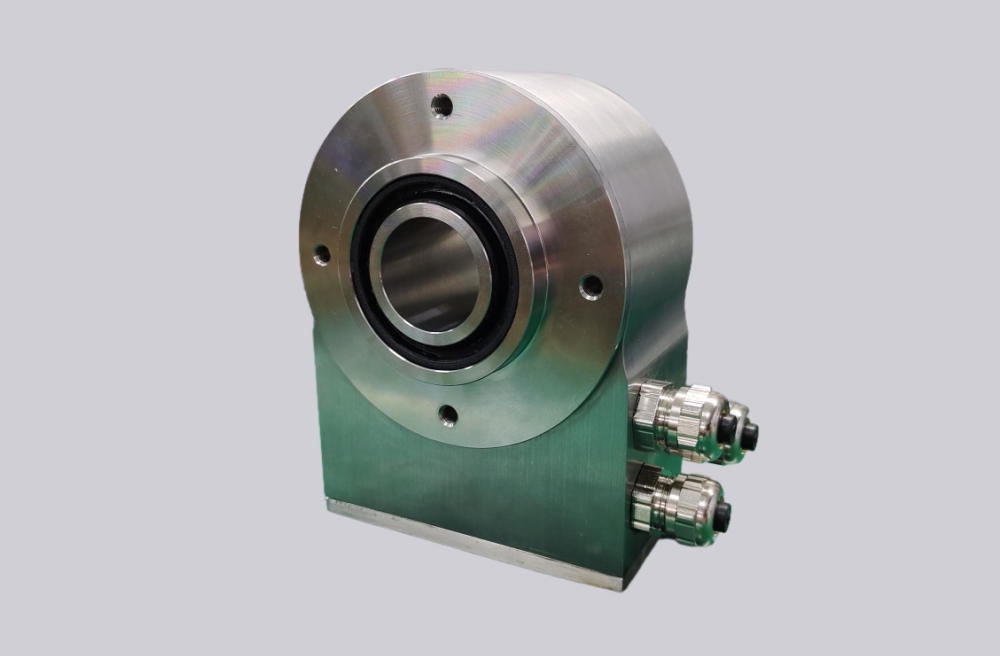

In industrial environments, encoder accuracy is influenced not only by the encoder’s internal manufacturing tolerances, but also by installation conditions, mechanical coupling, and the overall drivetrain design. Factors such as shaft misalignment, excessive axial or radial loads, and mechanical backlash can significantly affect the final measurement accuracy.

Repeatability describes the encoder’s ability to provide consistent output values when returning to the same position under identical conditions. In most closed-loop control systems, repeatability is often more critical than absolute accuracy. As long as repeatability is stable, control algorithms can compensate for systematic errors and achieve reliable motion control performance.

3. Why Higher Resolution Is Not Always Better

During encoder selection, some users tend to prioritize high resolution, assuming that higher resolution automatically leads to better system performance. In reality, if the mechanical system contains play, elastic deformation, or transmission errors, excessively high resolution may amplify noise rather than improve control quality.

For example, in heavy-duty machinery or long-shaft transmission systems, mechanical limitations often dominate overall system performance. In such cases, matching the encoder resolution appropriately to the mechanical characteristics of the system can improve stability and long-term reliability more effectively than simply increasing resolution.

4. System-Level Factors Affecting Measurement Accuracy

A rotary encoder functions as part of an integrated control system, and its performance must be evaluated at the system level. Controller performance, signal filtering strategies, communication latency, and system response time all influence the final measurement results.

Environmental conditions are equally important. In applications involving high temperatures, strong vibration, or severe electromagnetic interference, even an encoder with high theoretical accuracy may fail to deliver reliable results if proper protection and installation measures are not implemented. Therefore, encoder selection should always consider both technical specifications and actual operating conditions.

5. Practical Recommendations for Engineering Selection

In real-world applications, engineers should balance resolution, accuracy, and system complexity according to specific requirements. For high-dynamic and high-precision positioning tasks, resolution and repeatability should be prioritized. In contrast, for continuous operation or heavy-load applications, greater emphasis should be placed on mechanical robustness, bearing life, and environmental resistance.

By understanding resolution and accuracy from a system-oriented engineering perspective, it is possible to achieve reliable and stable industrial motion control while avoiding unnecessary cost and complexity.

SIVIDI

请到「后台-用户-个人资料」中填写个人说明。

Latest Articles

Copyright © 2025 SIVIDI Inc. All Rights Reserved. Sitemap